Blanking Lines

Homepage / Press Feeding Systems / Blanking Lines

Slide

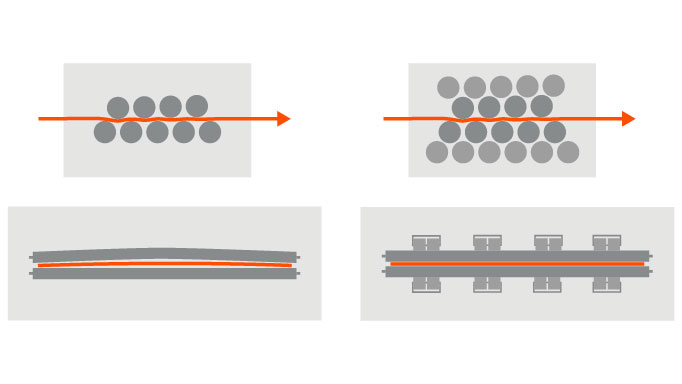

Blanking lines equipped with precision straightener and high performance feeder group for being used at blanking operations. It’s possible to produce large volumes of blanks in standard or complex geometric shapes. Good results about leveling can be achieved even for high strength materials with specially selected leveler rolls diamaeter according to the application and support rolled structure.

Special stacking systems can be design for press end of line operations. With these systems blank stacking can be done fast and efficent way.