Compact Feeder

General Specifications

Compact Line Sheet Width Capacity

80~800mm

Compact Line Sheet Thickness Capacity

0,6~6,0mm

Decoiler

Coil Loading Capacity

8000 Kg

Drum Type

Hydraulic expansion

Hydraulic Unit

BOSCH REXROTH / HYDAC

Drum Number

Single

Coil Hold Down Arm

Hydraulic

Coil Hold Up Arm

Hydraulic and motorized

WATTDRIVE

Coil Inner / Outer Diameter

480~520mm / 1600mm

AC Motor Power

4kW

WATTDRIVE

Gearbox Type

Conical type, helical geared, low backlash

WATTDRIVE

Power Transfer Type

Sprocket

SKF

Speed Control

Yes

SIEMENS

Brake System

Pneumatic disc brake

TWIFLEX

Loop Control

Distance controlled laser sensor

SICK

Coil Loading Car

Yes

Coil Centering

Servo motorized lateral guides

SIEMENS

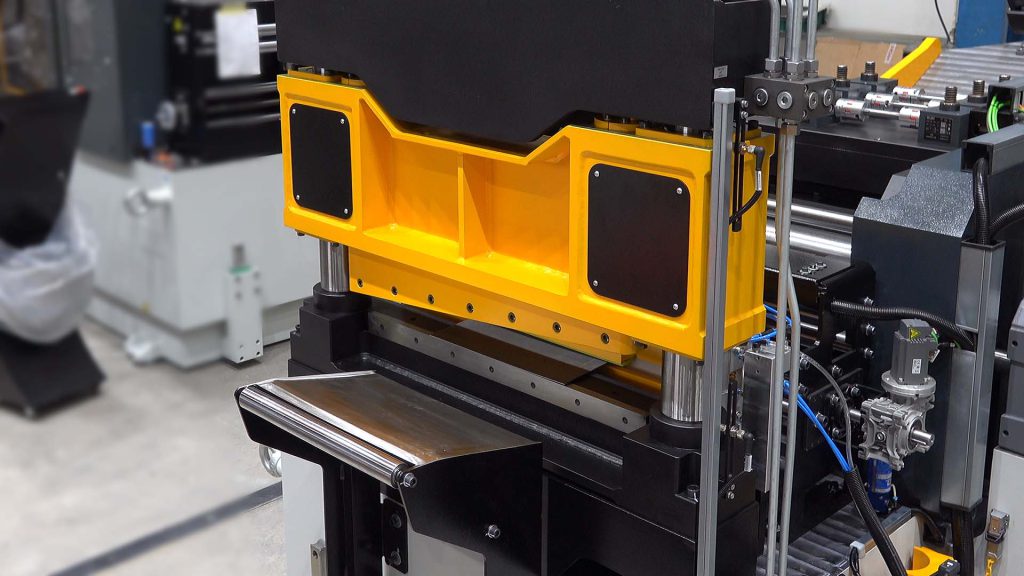

Straightener Feeder

Sheet Metal Bending System

Hydrulic driven bending arm

BOSCH REXROTH / HYDAC

Number of Pinch Rolls

2

Openable Rolls Group

~20 degrees crocodile openable hydraulic driven

BOSCH REXROTH / HYDAC

Straightener Drive Type

Gear driven

Straightener Adjustment

Servo Motorized, 3 pieces

SIEMENS

Straightener Rolls Pressure Gearbox

3 pair, shaft fitted

Straightener Support Rolls

Yes

Straightener Rolls Arrangement

4 Bottom / 3 Top

Number of Straightener Rolls

7

Diameter of Straightener Rolls

100mm

Number of Feeder Rolls

2

Diameter of Feeder Rolls

125mm

Feeder Rolls Pressure Adjustment

Pneumatic

FESTO

Servo Motor Power

24Nm

SIEMENS

Gearbox Type

Conical type, helical geared, keyless, shrink disc, low backlash

WATTDRIVE

Piloting System

Hydraulic system

BOSCH REXROTH / HYDAC

Feeder Height Adjustment System

Motorized

Sheet Positioning Inside Die

Hand Wheel

EUCHNER

I/O Communication Type

On board, IP67 protection class

Servo Motorized Lateral Coil Guides

Loading the sheet coils on the drum with centering, operated by

servo motorized lateral side guides. When the operator inputs

the sheet width on the operator panel these side guides expand

laterally from the center of the drum until the entered sheet

width. By the way it prevenets the off center aligning of coil. Coil

loading duration becomes very fast and safer.

Drum Jaws Nail Sysytem

Nails between the drum jaws prevents the stucking of end of

coil. With these nails end of teh coil can be used without any

problem

Crocodile Opening System

Straightener feeder group opened from the inlet side with

approximate 20 degree angle. By the way it helps to introduce

the sheet easily to the straightener group. This feature decrease

the loss of time during the new coil loading. Opening of the

group driven by hydraulic cylinders.

Coil Loading Car

Coil can be loaded safely by a crane or forklift on the coil

loading car. Z axis on the car driven by a hydraulic cylinder and Y

axis by an A/C motor. To prevent the tilting of the coil during the

loading there are safety pillars on the car.

A100 Die Recognizing System - Servo Motorized Side Guides

The guides at the inlet and outlet side of the straightener feeder

group adjusted by servo motors. When the operator inputs the

sheet width to the panel, these guides moves laterally from the

center and goes to reference point. By the way sheet driven to

the die from the center of the line. This setting is very fast and

accurate with the help of servo motors. Die recognizing system

can be included with the package.

A100 Die Recognizing System - Servo Motorized Straightener Adjustment

Top rolls of the straightener group are adjustable individually.

This control helps tp make flattnes setting accurately. All rollers

at the top driven vertically by servo motors to make the pressure

adjustment. Rollers adjusted automatically accurding to input

value from the operator panel. Actual position of the rollers can

be observed from the operator panel.

A100 Die Recognizing System - Motorized Height Adjustment

Height adjustment of straightener feeder group automatically

driven by a motorized system. When die height entered to the

operator panel, machine rise or descend automatically according

to entered value. Position control done by lineer ruler on the

body.

Support Rolled Straightener and Feeder Group

Rollers on straightener and feeder groups are supported from

bottom and top with support rolls. By the way, rolls bending

decrease to minimum level. Decreasing of the rolls bending

provides high straightening quality.

SIEMENS SIMOTION D - the high-end motion control system - External Encoder Control

With the external encoder, feeded sheet length controled

another time. Feeding rolls measurement and encoder wheel

measurement controlled instantly during the feeding operation.

Possible slipping of the sheet durning the feeding operation

tolerated instantly.

All servo equipment on a machine will be used as SIEMENS

Sheet Positioning Inside Die with Hand Wheel

die, the press is used in single stroke mode and the feeding

system in manual mode until the first part falls. The advance of

the sheet to the next operation after each stroke is done by the

hand wheel with much more precisely and quickly. Thus, both

the start time of mass production will be shortened and safer

work will be provided in terms of safety.

Hydraulic Guillotine

Cutting Force

220kN

Cutting Capacity

6,0mm @600mpa

Blade Gap Adjustment

No

Guillotine Shear; cutting shear cuts sheet metal between

feeder and die in case of operation stop for any reason.

Feeder Guideway

Between the feeding rollers and press bolster, there is a

guideway that functions as bridge in order to moving sheet

without bending.This guideway connected on the straightenerfeeder

body, it acts in same way as the height setting changes.

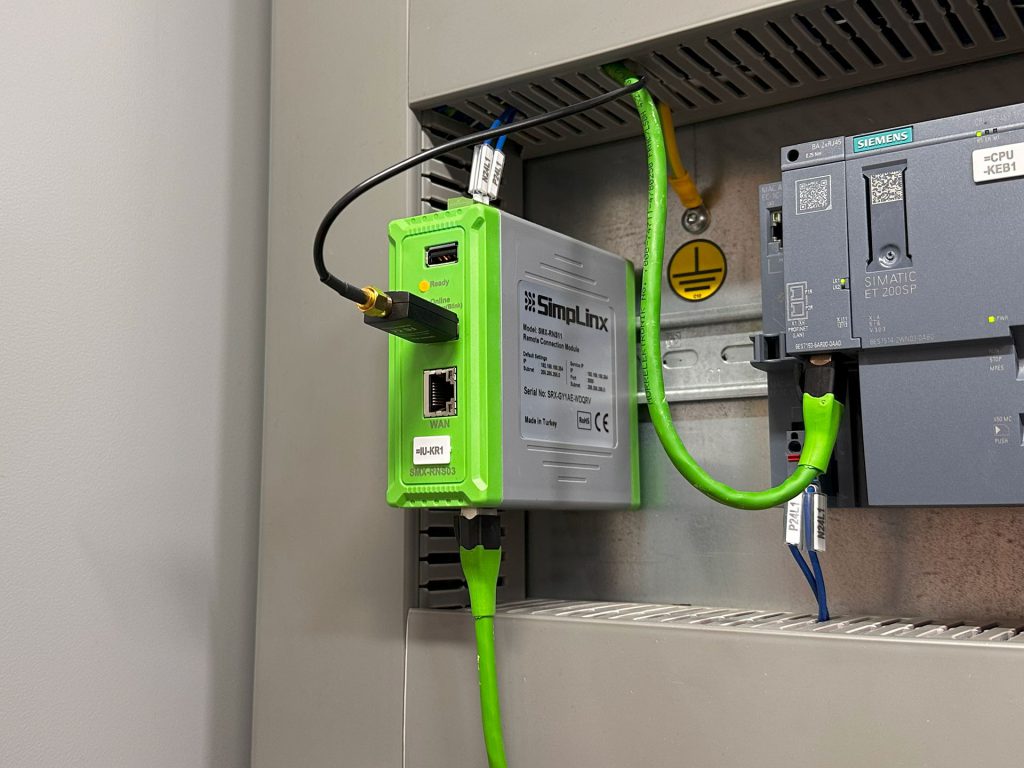

SimpLinx Remote Connection

Our machines are always accessible with the SimpLinx remote

connection module. Intervention and diagnosis can be done by

connecting to your machine remotely. Processes in the fastest

way possible by our technical service team in case of any

malfunction.

It helps to connect without getting stuck cause of your port or

firewall restriction procedures.

Safety Package

Safety Controller

SICK

Fence System

SURFENCE

Safety Door

SURFENCE

Locking System

EUCHNER

Light Barrier

SICK

Roll Lubricator

Lubricatin Type

Felt

Rolls Diameter

110mm

Tank Type

Pressure - 20Lt

Control Type

Line HMI

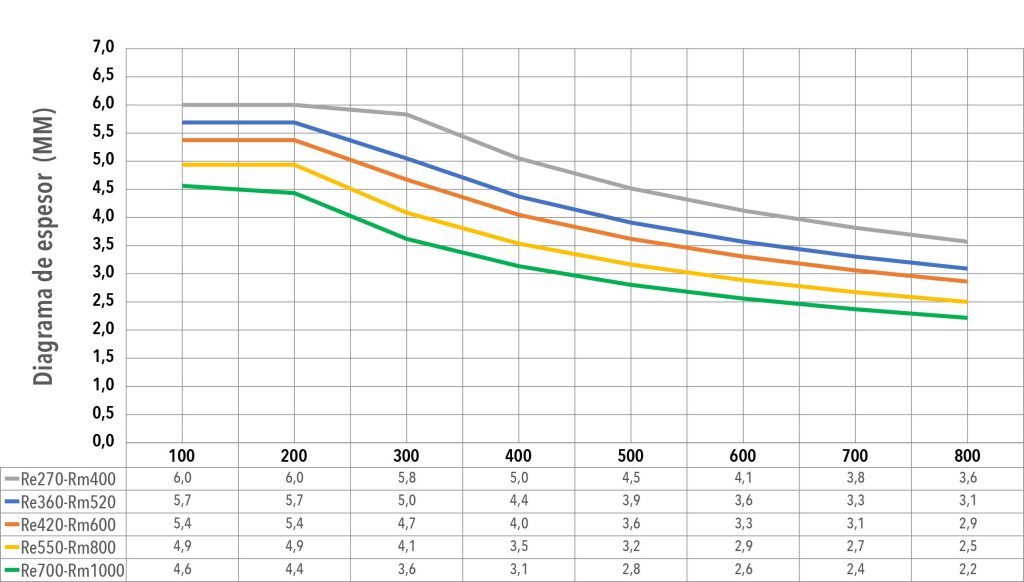

Thickness Diagram

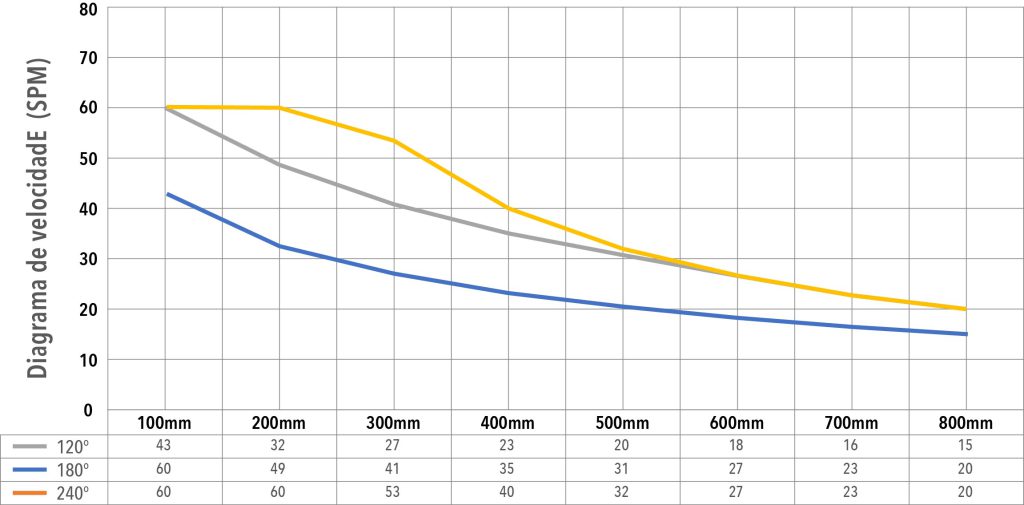

Speed Diagram

Feeding Speed

50m/min

Process Speed

16m/min

Piloting Time

400ms

Acceleration

3m/sc2